| 🏷️ Brand | TecUpdater |

| 🔌 Connector Type | Self solder seal butt connector |

| 💧 Waterproof | Yes (adhesive heat shrink) |

| 📦 Pack Size | Set of 10 |

| 🔥 Installation Method | Heat activated solder & shrink |

| 🛡️ Warranty | 1 Year manufacturing defect warranty |

| 🔁 Return Policy | Exchange only |

Waterproof Solder Seal Butt Splice Connectors for Automotive and Marine Wiring

Why This Product Exists

Traditional wire joints rely on crimp connectors or manual soldering. Crimps can loosen over time due to vibration, while manual soldering often lacks proper insulation and moisture protection unless multiple steps are followed.

Self solder seal butt connectors solve these issues by combining:

Soldering

Insulation

Waterproof sealing

into a single installation step. This makes them particularly useful in automotive and marine environments where heat, moisture, and vibration are constant factors.

Where These Connectors Are Used

These connectors are commonly used in:

Automotive accessory wiring

Marine electrical systems

Engine bay repairs

Underbody and exterior wiring

Dashcam, lighting, and sensor connections

Once heat is applied, the connector forms a sealed joint that resists corrosion and maintains electrical continuity even in harsh conditions.

How the Self Solder Seal Works

Each connector has:

A central low-temperature solder ring

Heat-shrink tubing for insulation

Adhesive lining for waterproof sealing

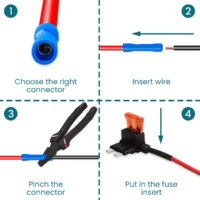

Installation steps:

Strip both wire ends

Insert wires into the connector from each side

Apply heat evenly using a heat gun

Solder melts and flows into the joint

Heat-shrink contracts and seals the connection

No crimping is required, and the finished joint is mechanically stable and electrically secure.

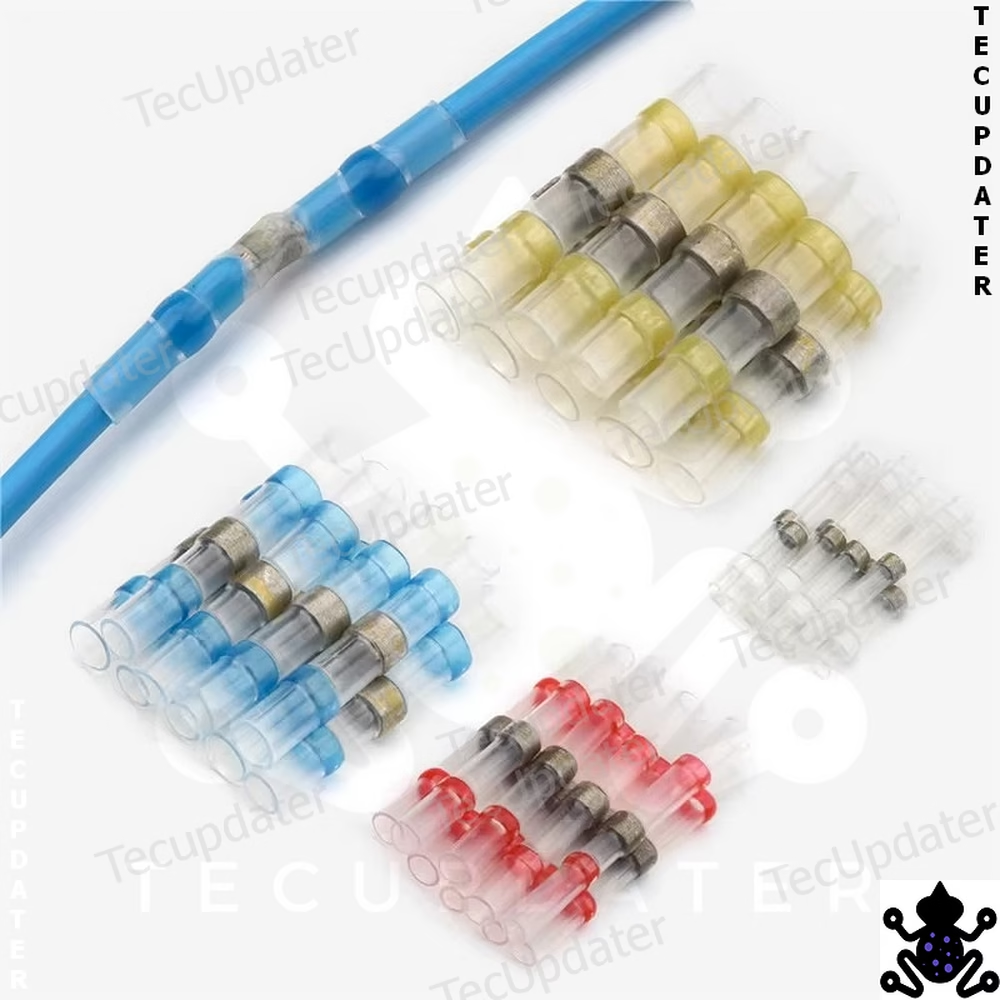

Size Options Explained

This product is available in two commonly used sizes, each sold as a set of 10 connectors:

SST-S21 – Suitable for thinner automotive signal and accessory wires

SST-S31 – Suitable for slightly thicker power and ground wires

Selecting the correct size ensures proper solder flow and sealing.

Installation Notes

Use a heat gun for best results

Avoid open flame for controlled heating

Ensure wires are clean and properly stripped

Allow the joint to cool before movement

Correct installation results in a strong, sealed joint without exposed conductors.

Who Should Buy This

This product is ideal for:

Automotive electricians and installers

Marine wiring repairs and upgrades

Enthusiasts installing accessories cleanly

Anyone needing waterproof wire joints

Who Should Not Buy This

This product is not suitable if:

You need temporary or removable connections

You do not have access to a heat gun

You prefer traditional crimp-only terminals

Variants / Options

SST-S21 – Set of 10 connectors

SST-S31 – Set of 10 connectors

Each size is sold separately.

Installation Logic / Behaviour Explanation

Once heat is applied, the solder creates a permanent electrical joint while the outer sleeve shrinks and seals. The adhesive lining prevents moisture ingress, making the joint suitable for long-term use in exposed locations.

Vehicle Compatibility

Suitable for use across vehicles and applications including:

Automotive

Volkswagen, Skoda, Hyundai, Kia, Tata

Passenger cars, SUVs, commercial vehicles

Marine

Boats and watercraft with insulated wiring systems

Compatibility is based on wire gauge, not vehicle model.

Benefits

No crimping required

Waterproof and corrosion resistant

Clean professional finish

Strong electrical continuity

Ideal for vibration-prone environments

FAQs

Do I need a soldering iron?

No. The solder is pre-installed and activates with heat from a heat gun.

Are these suitable for engine bay wiring?

Yes. When installed correctly, they withstand heat and vibration well.

Can these be used on marine wiring?

Yes. They are designed for waterproof applications including marine use.

Are these reusable?

No. Once heated and sealed, the connection is permanent.

Reviews

There are no reviews yet.